The standard East Penn legs are basically 1" x 12" that fit between the modules at the connection points. They can become very cumbersome during setup and break down, I wanted to find an alternative. Several club members have created different legs with varying success. Some use 2" x 2" wood either bolted on during setup or hinged under the module, others use angle aluminum the same way. An aluminum angle/wood composite replacement for the 1" x 12" is often used but it has the same problems as the original. I want something that is easy to set-up, no bolts and not a sandwich between modules. I want it to follow my scheme of keeping the module lightweight for transporting. It must be sturdy enough to support the module but it doesn't have to be completely rigid, experimenters before me found that even a wobbly module standing alone becomes solid and rigid when bolted to other modules. I also want adjustable legs. I have always put T-nuts and padded bolts in my standard legs to allow for hilly floor compensation.

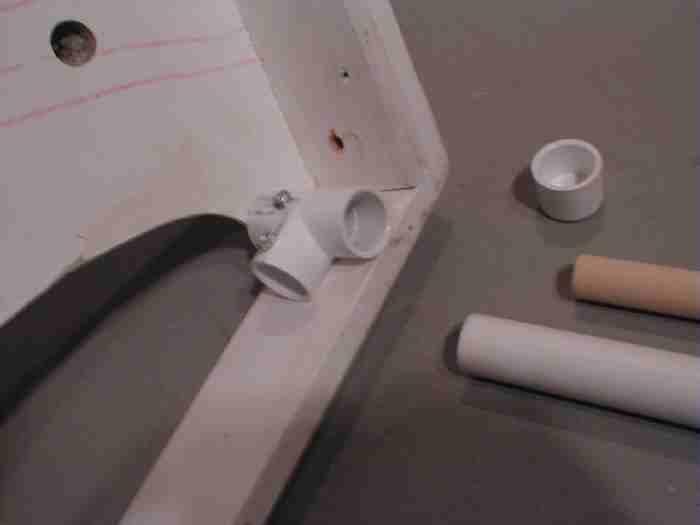

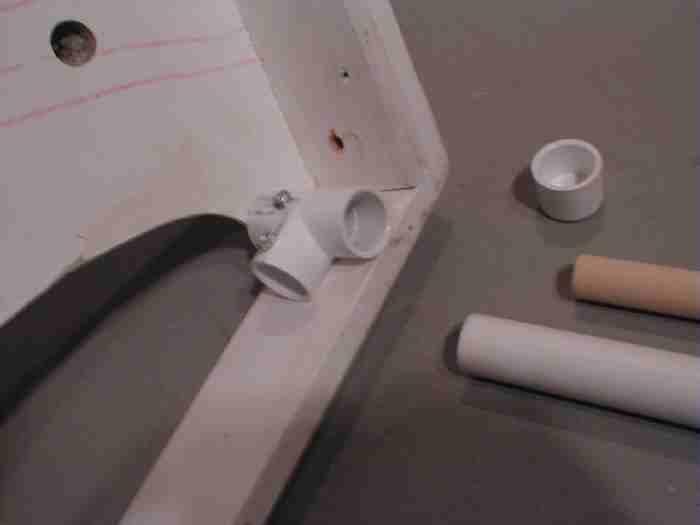

I settled on 1" PVC pipe. I bolted pipe Tees to the module framework then slip a piece of pipe into it when it is time to setup. The top of the pipe leg must be sanded down just a little to make a tight slip fit that can be removed with a twist. Without sanding the pipe wants to stay in the Tee. I did my sanding on a 6" disk sander, just keep the pipe turning and don't stay in one spot too long. To add rigidity to this plastic pipe I inserted a 1" wood dowel. The dowel is a loose fit and I'll have to pin it in place before I'm done. The dowel changes it from something that that looks like it may collapse any second to a freestanding module that won't fall on its own. The pipe legs could be made lighter by using 1" od pipe or tubing inserts, I found that a bathtub curtain rod is almost perfect, they just cost three times as much as the wood dowel. I intend to put a height adjuster on the bottom of my legs. I experimented with a threaded cap but the threads are tapered so the cap stays put, after a couple turns it can't be removed. I may just go to the T-nut and padded bolt like I use on the standard legs. I could mount them into a pipe cap or even into the bottom of those wood dowels.

If you have any ideas about improving these legs please let me know, I'll give anything a try.

Below is a shot of one leg showing the pipe and dowell that goes inside. A slip-on cap for the bottom is also shown, and the pipe Tee is bolted to the module.